It may be one of the most important sites in automotive history -- the home of the first moving assembly line where workers were offered $5 a day -- but few signs remain of the old Ford plant in the struggling Detroit suburb Highland Park beyond the Model T name on an adjacent shopping center.

That could change if a Motor City community and economic development group has its way. The Woodward Avenue Action Association is raising money to save the historic factory and help turn it into a tourist and learning center.

Read more: Happy Birthday, Dear Henry: Ford Founder Would Turn 150

Designed by legendary architect Albert Kahn and once known as the Crystal Palace because of its large windows and abundant natural light, the Highland Park Assembly Plant was actually the third Ford Motor Co. factory and the second to produce the Model T. But with huge demand for his “Tin Lizzie,” Henry Ford desperately needed to increase production.

Read more: Is Cadillac's Elmiraj Real or Illusion?

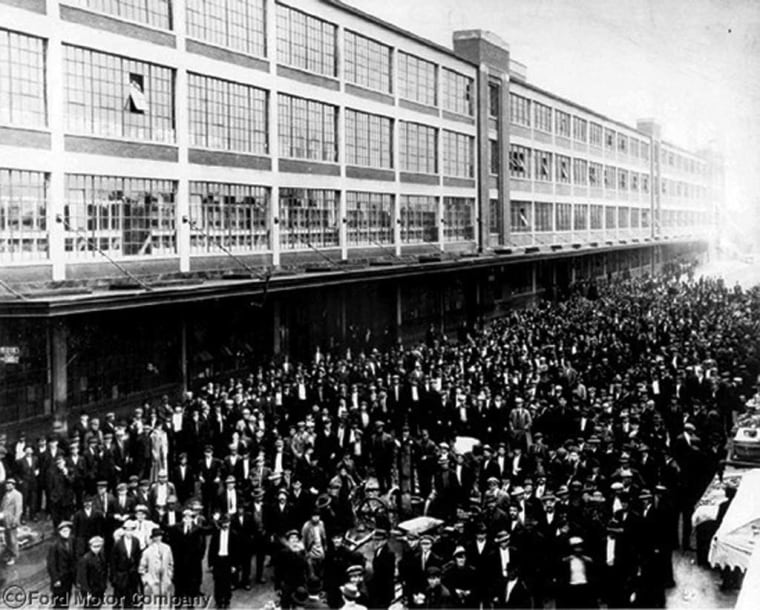

He also needed to ensure a reliable source of labor at a time when workers routinely quit due to the grueling demands of the automotive assembly line. That led the industry pioneer to offer $5 day. But Ford had another motive in mind. It also created a new class of increasingly affluent customers whom he rightly assumed would also buy the Model T rather than taking the street car to work.

Read more: Tesla Model S Gets Best-Ever Crash Safety Rating

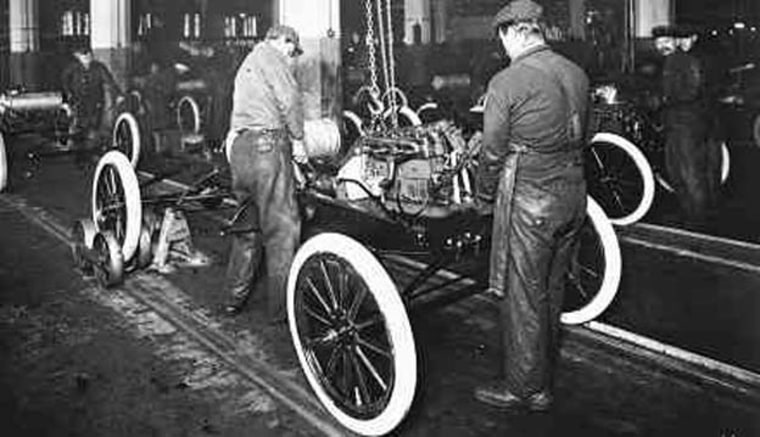

The factory first opened in 1910 but Ford continued to struggle with booming demand for the little car. He came up with an idea reverse-engineered from Midwest slaughterhouses where carcasses were pushed along a conveyor, each worker hacking off a specific slice of meat. Highland Park began pulling partially-assembled Model T bodies along a conveyor – initially by rope – with workers at each station assigned to complete a specific task.

The move helped Ford steadily reduce production costs, dropping the price of the car to $300 by the end of its run from $800, when it was first introduced.

Read more: Picking the best-of-the-best at the World's Most Exclusive Car Show

The plant’s taxes and jobs helped turn the surrounding community into one of the most affluent in the country, but despite its original breakthroughs, the multi-story plant grew increasingly outdated and what was once described as “the factory that changed the world” was largely abandoned by the late 1920s as Ford Motor Co. opened its even more massive factory complex along Detroit’s Rouge River.

Some component and tractor assembly operations continued for a while but the plant has been abandoned, with some portions surviving as a company storage depot, and section as a clothing warehouse. The surrounding suburb has also faded away and is now under emergency financial management.

Read more: Rare Ferrari Draws Record $27.5 Mil Auction Bid

Despite being added to the National Historic Landmark registry in 1978, there have been concerns that the old Model T plant could suffer the same fate as other once-prosperous Detroit factories – such as the Packard plant a few miles away that has been steadily collapsing, the prospects of saving it growing increasingly dim.

The Woodward Avenue Action Association’s campaign is a modest one. The group, known as WA3, needs $550,000 to acquire several of the remaining buildings on the property. It has already received more than $400,000 in grants and hopes to raise another $125,000 to secure the purchase.

Read more: Chrysler Reveals Ram Rumble Bee Performance Truck Concept

Eventually, organizers say, they will need still more cash to begin restoration and renovation. Several options are under study for the building’s future, including a museum and learning center.

The "$5 a day" campaign has a deadline of September 19th to complete the initial financing package. It could prove appropriate as that deadline comes just weeks before the 100th anniversary of the moving assembly line which, a statement from Ford notes, began operating on Oct. 7, 1913, “creating and defining the industrial age.”

Read more: Buffett Boosts GM Holdings by 60%

Editor's note: The writer of this story has donated to this campaign.