Give a man a gadget, and you feed his tech needs for a day. Teach him to make gadgets, and he can feed himself — and a few savvy venture capitalists — for life.

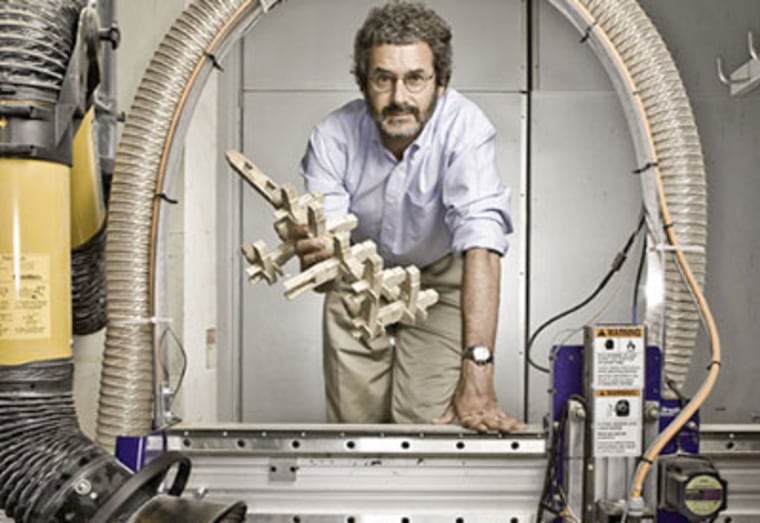

Such is the thinking of Neil Gershenfeld, a 48-year-old physicist and MIT professor and the inventor of what he calls the Fab Lab. A Fab Lab (short for fabrication laboratory) is a package of tools designed to make essentially any object.

The kits can include a laser cutter, computer-controlled wood router and a miniature mill for drilling circuit boards, all for around $50,000, including open-source software, batteries and micro-controllers.

Those appliances and materials, Gershenfeld says, are all anyone needs to build whatever he or she can imagine: panels for roofing a house, a simple computer or a better mouse trap. "Basically, the goal is to create a 'Star Trek'-style replicator in 20 years," Gershenfeld says matter-of-factly.

For now, Gershenfeld's project is focused on bringing an early version of that replicator to the masses: He's shipped 26 Fab Labs around the world since 2002. Shepherds in Norway have used a Fab Lab to create radio-frequency ID tags for tracking wandering sheep.

The South African government is working with Sun Microsystems and Cisco on building simple Internet-connected computers that hook up to televisions and cost just $10 each.

For ordinary people

The latest Fab Lab was shipped to Afghanistan in June, where it will fashion customized prosthetic limbs. Gershenfeld says he receives a lab request every day.

"The Fab Labs tap into this wellspring of interest from ordinary people in getting the means to create their own technology," says Gershenfeld.

But for all that emphasis on self-sufficiency, Fab Labs have so far been oddly dependent on charity — the project has been fueled by about $2 million in funding from the National Science Foundation along with money from local non-profits and governments.

That's why Gershenfeld has been searching for a way to make his Fab Lab network self-sustaining. His newly evolved answer is the Fab Fund, a for-profit project launched a year ago by Gershenfeld's brother Alan and fellow venture capitalist Michael Angst.

The Fab Fund is a test of what its founders call "micro-venture capitalism." Its capital, currently around $200,000, will be invested in for-profit businesses that manufacture their products in Fab Labs around the world. Each Fab Lab, instead of building just what its owners design, can earn its keep by spending a few hours building someone else's Fab-Fund-sponsored product.

The Fund's first investment is in a company that will sell a toy called GIK, or "Great Invention Kit," a system of cardboard cut-out panels that range from a size used to assemble miniature figures to a scale large enough to build forts.

A first round of GIK, which Gershenfeld's own children invented in their family's Fab Lab, is currently being cut in a lab in the South Bronx. Eventually, GIK designs will be customized online by kids around the world and sent to any Fab Lab that has a few hours' downtime — or even better, a lab near a customer's home, to lower shipping costs.

Aside from GIK, the Fab Fund has received proposals from businesses pitching gadgets that range from clothing accessories to super-cheap, long-range antennas to an attachment that converts a cellphone to a remote control. All hope to use a Fab Lab's spare hours to either prototype their products or build small, customized batches.

The goal, Gershenfeld says, is to show that distributed manufacturing can turn a profit. Eventually, he hopes many funds will throw their capital into the Fab Labs ecosystem.

Replicating Fab Labs

For Gershenfeld, self-sustaining fabrication is the culmination of decades of obsession with the culture of DIY. As a child, the curly-haired engineer spent hours building his own music synthesizer and calculator, sitting for hours in front of an oscilloscope, trying to understand the minutiae of circuitry.

Gershenfeld's techno-lust continued into his college years, where he lamented that his time was spent on mere academia, while hands-on building was left to trade schools. "I couldn't understand why an interest in making things was taken as a sign of lesser intelligence," he wrote in his 2005 book "Fab."

Since 1998, he's been working to bridge that gap between learning and making, teaching a class at MIT called "How to Make (Almost) Anything." He's also founding a global degree program, the so-called Fab Academy, that certifies students in Fab-style building from digital designs.

But there's an even more ambitious element of Gershenfeld's plan to spread DIY around the world in small, self-sustaining workshops. He and his MIT team are working on building a Fab Lab that can itself build every element of a Fab Lab: In other words, a Fab Lab that can reproduce.

They've already used a Fab Lab to build working prototypes of a laser cutter and the computer equipment used for design projects.

That means that in decades to come, Gershenfeld hopes not just to have created the "'Star Trek' replicator" that he dreams of, but replicators that replicate themselves, spreading around the world in a massive, self-perpetuating, self-funded network.

"If anyone can make anything, anywhere," Gershenfeld says, "It fundamentally changes the meaning of business."