Here’s an amazing but true story to tide you over until the Spider-Man movie appears this summer: Cow and hamster cells can produce spider silk of their own, given the right kind of genetic coaxing. This latest twist in the quest to reproduce spiders’ remarkable fiber, for use in everything from bandages to bulletproof vests, is reported in Friday’s issue of the journal Science, published by the American Association for the Advancement of Science.

Spider silk is nature’s miracle fiber: three times stronger than Kevlar, ounce per ounce stronger than steel, able to stretch up to one-half its normal length, and packaged as a minuscule filament 80 times thinner than a human hair. It’s even been said that a strand of spider silk the width of a pencil could stop a Boeing 747 in flight.

It’s no wonder, then, that scientists have longed to mass-produce spider silk for a variety of items. Researchers think spider silk would be the perfect material for wound bandages, parachutes, ropes, nets, artificial tendons and ligaments, aerospace tethers and bulletproof clothing. The Science team includes researchers from the U.S. Army, who envision future soldiers going into battle protected by lightweight antiballistic armor made of spider silk.

Spider silk is also a “green” technology, biodegradable and created without harmful chemicals. Its harmless decay makes it an attractive material for a variety of applications, ranging from surgical sutures that dissolve during the healing process to environment-friendly fishing line.

Silk without spiders

The grand plan to harvest spider silk has one small hitch: The spiders just aren’t that cooperative. Unlike the silkworms that churn out raw material for your silk pajamas, spiders tend to eat each other when they’re crowded into a “factory farm” environment. Instead, scientists are searching for ways to reproduce spider silk proteins and spin them under controlled conditions in the lab.

These scientists are especially interested in replicating dragline silk, the extremely strong silk that forms the framing threads of webs and the safety line that anchors spiders like a bungee cord as they navigate their webs. Dragline silk is composed of two proteins, rich in alternating blocks of alanine and glycine amino acids. The alanine blocks form crystalline structures that give silk its strength, while less orderly glycine blocks provide the silk’s elasticity.

After the genes that encode these proteins were first identified in species like the golden orb-weaving spider, scientists isolated and inserted the genes into yeast and bacteria cells in an attempt to generate silk proteins. These simple organisms have a hard time processing silk’s highly repetitive structure, however, and they produce unnaturally short proteins, says Costas N. Karatzas of Nexia Biotechnologies.

Reasoning that mammalian cells might be able to handle the complexity of silk protein translation, the Science researchers inserted silk DNA from two spider species into baby hamster kidney cells and cow cells. The mammal cells proved to be up to the challenge, incorporating the spider DNA into their own genetic code and secreting silk proteins of comparable length to natural spider silk proteins.

Mimicking the mechanics

Spiders spin silk by passing a liquid crystal solution of these proteins through a twisting path in their silk glands, forcing the protein molecules to align themselves before being released from the spider through organs called spinnerets. Once the silk hits the air, it hardens into a flexible and tough fiber.

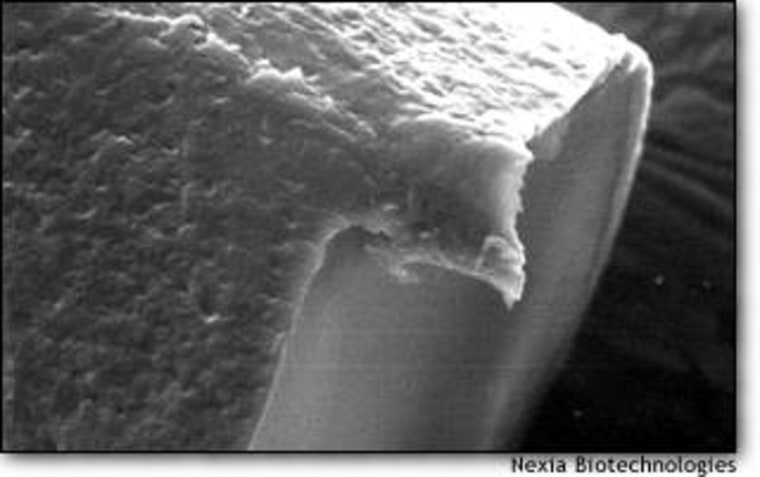

To mimic this process, Karatzas and colleagues spun silk proteins secreted by the hamster and cow cells, using a mechanical pump and spinneret. The proteins were dissolved, spun and further stretched in a simple bath of ethanol and water, rather than the harsh chemical solvents used with yeast or bacteria-produced silk or synthetic fibers like Kevlar.

The resulting silk is similar to natural spider silk, but the scientists haven’t quite managed to duplicate the unique combination of mechanical properties that make silk such a unique fiber, says Jeffrey D. Turner, president of Nexia Biotechnologies. Spider silk is famous for toughness — “think of how a cheap steak resists chewing,” Turner says — as well as its elasticity, and its strength, or ability to bear weight. The new lab-spun fibers match natural silk in toughness and elasticity, but they aren’t quite as strong.

Although the researchers appreciate spider silk’s superior design, refined by 400 million years of evolution, spinning at the speed of spiders won’t do for commercial applications. The Science team is searching for ways to improve spinning speed, with techniques that quickly remove water from the protein bath and force the protein molecules into alignment faster. The scientists would also like to create multifilament yarns by spinning several hundred threads at once.

“Ultimately, we want to make spider silk that mimics or does better on all the properties of natural silk combined,” Turner says.