Step into the nanoworld these days, and here are some of the things you might see: a single DNA molecule clad in a thin layer of gold that acts as a one-dimensional quantum wire. An atomic-scale box that opens and closes on its own. A robot arm flexing plastic mini-muscles. A cell-sorting chip equipped with tiny soft valves and pumps.

These seemingly sci-fi devices, reviewed in Friday’s issue of Science, are measured on a mind-boggling scale of a billionth of a meter, with average sizes about the width of the period at the end of this sentence. But this hasn’t stopped scientists on nanotechnology’s frontier from thinking big, envisioning everything from single-cell laboratories to a wireless revolution that may put your current cell phone to shame.

Race to the bottom

Consider the shrinking microprocessor, jam-packed with smaller transistors each generation. Or the quest to untangle our DNA gene by gene, or even the desire to doctor sick cells at the molecular level. In many ways, current science is in a race to the bottom, and nanotechnology researchers are looking for ways to build, manipulate and explore at these vanishingly small sizes.

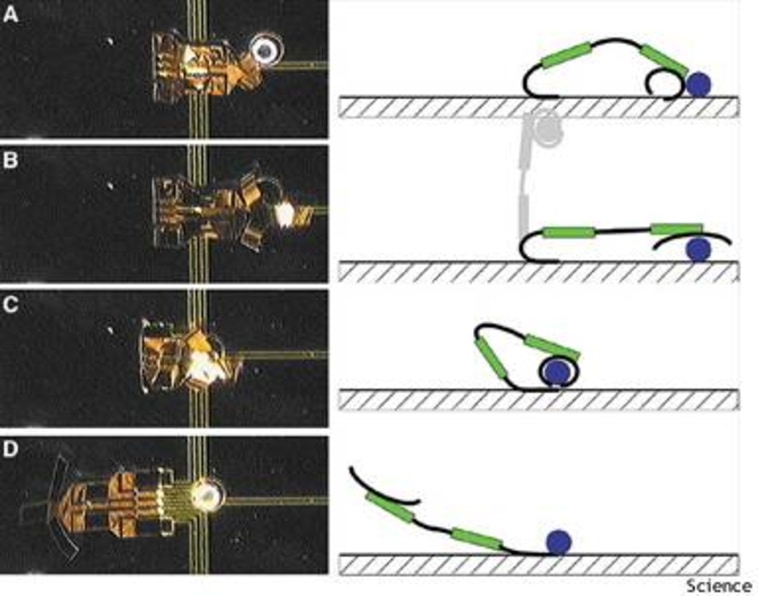

Edwin W.H. Jager and Olle Inganäs at Linköpings Universitet in Sweden and their colleagues are developing nanostructures called actuators — mechanical devices that can move or control things — to handle biological materials like single cells, bacteria, or molecules in salty liquids like blood plasma, urine, or cell culture medium.

The actuators are built from thin layers of polymer deposited over another thin layer of gold. This double layer is then shaped into a device or into the components of a device by a process called photolithography, where a pattern is carved out of the polymer bilayer with the help of ultraviolet light.

The polymer that Jager and colleagues use, called polypyrrole, shrinks and swells like a contracting muscle when it receives a jolt of electricity. Like the biceps that power the movement of the bones of your arm, the changes in the volume of the polymer furnish the force behind the movement of the researchers’ nanodevices.

Yet even the most accomplished bodybuilder probably couldn’t match the strength of these miniature mechanical muscles. Jager and colleagues tested their performance by lifting millimeter-sized thin glass slips with hinges made of the polypyrrole actuators, to see if they could rotate 180 degrees and back again while carrying their glass load. For devices with a polymer thickness of 0.9 micrometers, the ratio of the mass lifted to the mass of the hinge itself was 43,000 to 1.

“A good comparison in humans would be of one arm moving a 30 meter by 30 meter (100 feet by 100 feet) plate under water,” said Jager.

The polymer actuator can be operated for a few thousand cycles before the polymer and the gold peel apart from each other. The researchers are exploring ways to increase the adhesion between the two layers, such as roughing up the gold surface or using titanium instead of gold, creating a better chemical bond with the polymer.

Using these actuators, Jager and colleagues have manufactured a number of devices, most notably a 670-micrometer-long microrobot “arm.” The arm can grasp and move a tiny glass bead, opening up the possibility that a team of nanorobotic arms could move cells around a lab-on-a-chip.

The actuators also serve as hinges on tiny boxes that open and close on their own, suggesting microvials for drugs. By equipped these boxes with tiny sensors, Jager and colleagues have created clinics for the study of single cells. The researchers are also developing a “cell tapper,” which would thump on single cells and analyze the effects of this mechanical stimulation.

A soft touch

Engineering feats in stiff silicon may have set the stage for the current boom in miniaturization, but researchers are finding that a soft touch may be necessary to create other devices envisioned for the next generation of nanotechnology.

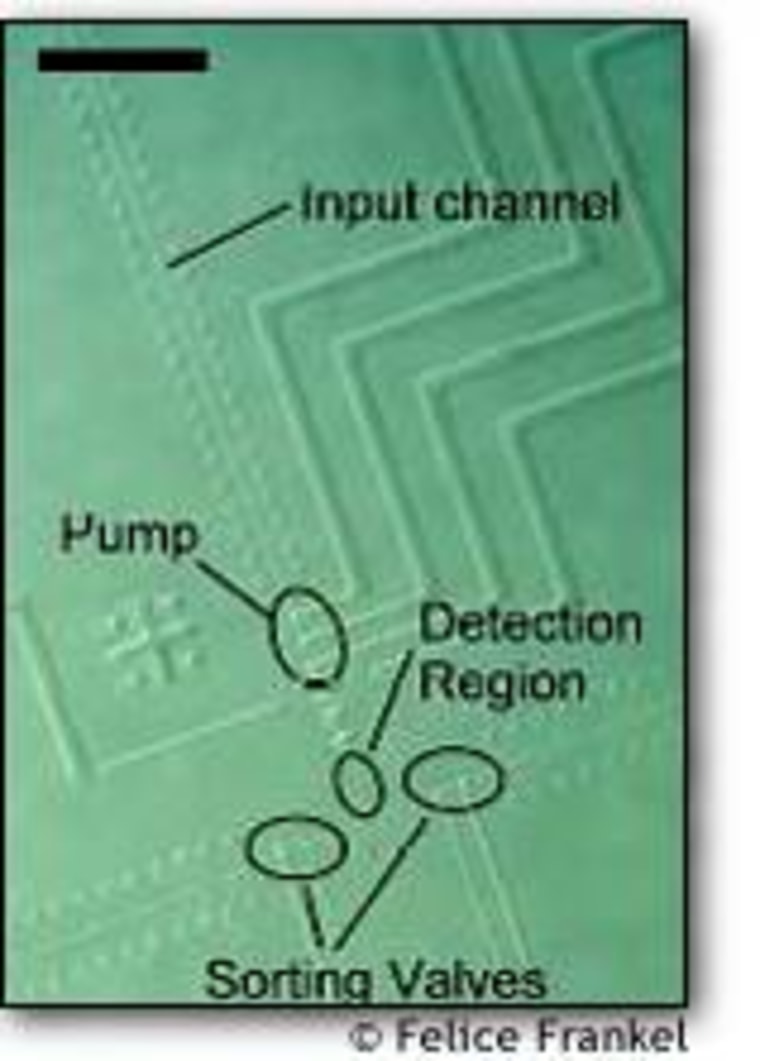

A lab-on-a-chip — designed to sort cells or cycle chemical agents through a sample of small molecules in search for new drug possibilities — needs a variety of moving parts that are flexible enough to handle fluid flow, form soft seals like macroscopic rubber washers, and occupy minimal space.

To meet this need, Stephen R. Quake and Axel Scherer of the California Institute of Technology have developed soft valves made out of rubbery polymer, fabricated within microscopic molds and activated by air pressure. When the valves are arranged in a row, they act as pumps that operate in the same way that the esophagus or intestine does, by contracting and forcing fluid through a channel.

Quake and Scherer have integrated these valves and pumps onto chip devices, including a cell sorter and a diagnostic assay, where they transport a few nanoliters of fluid per second.

Some biochemical assays show their results optically, often by means of a fluorescent marker. The researchers used soft polymers to create diffractive lenses that could be integrated along with the valves and pumps on these devices, efficiently ushering light in and out of the chip.

Part of the allure of these soft polymer devices lies in their price. Inexpensive materials and the molding method lend themselves to mass production and make the devices practically disposable, a boon to biological researchers with constant worries of contamination.

You might want to throw these devices out, but it would be hard to wear them out.

“We tested the lifespan of the valves, and found that they could open 4 million times without jamming, and that the 4 millionth time worked as well as the first,” said Quake.

Soft materials can also serve as the skeleton or template for electrical nanodevices, including nanowires and resonators.

Using a technique called molecular combing, the researchers stretched out a single DNA molecule and then used evaporation to coat the DNA in a thin layer of gold, to make a one-dimensional wire less than 10 nanometers wide and up to 60 nanometers long.

Breaking these wires to form a “diving board” structure creates nanoresonators with extremely high radio frequencies. These resonators, which are among the smallest ever made, may revolutionize future wireless telecommunications, said Quake.