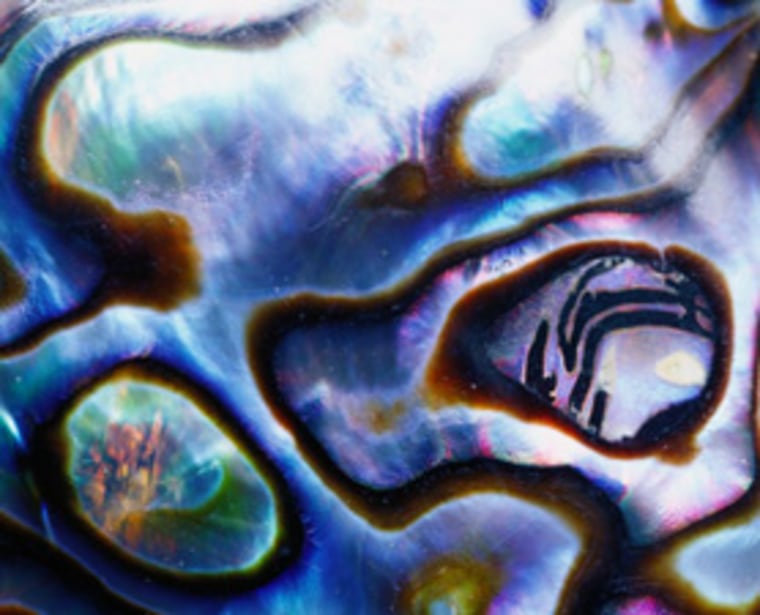

A natural pearl is a rare treasure, but new mass-produced mother of pearl could soon be as cheap and versatile as paper.

Flameproof yet flexible, thinner than office paper but 20 times as strong, the new material could eventually make aircraft lighter and comfortably protect police from bullets.

"Natural nacre is this perfect marriage of stiffness, strength and toughness," said Andreas Walther, a researcher at the Helsinki University of Technology and a co-author of a recent paper in the journal Nano Letters.

"Our artificial nacre compares very well to the natural material."

Synthetic nacre has long been a goal for both material scientists and biologists. For material scientists man-made nacre could provide strong, lightweight, cheap and environmentally-friendly material for a huge variety of products.

For biologists, synthetic nacre would provide a new way to study the complex mesh of soft protein and hard calcium carbonate that mollusks use as protection and women as decoration.

Artificial nacre has been produced before, but in small, labor-intensive amounts, said Walther. "To get even a few microns you had to dip a glass slide 1,800 times into various glass beakers," said Walther. The entire process could take anywhere from days to weeks to complete.

Walther and his other colleagues in Finland and Sweden aimed to reduce those hundreds of steps down to one. Drawing on the Scandinavian nations' experience in the wood processing and paper making industry, the scientists mixed hard clay particles and a soft, binding synthetic polymer.

The two materials are attracted to each other and arrange themselves in alternating layers. When drawn out like paper, square feet of artificial nacre emerges in minutes.

One layer of the new nacre looks like paper but is thinner, stronger, and stiffer than paper. One quality the new nacre lacks is toughness; it tears more readily than paper, said Walter.

The new nacre, however, is impervious to heat.

"The material doesn't burn," said Walther. "We placed a silk cocoon five millimeters behind the material and heated it to 2,000 degrees [Celsius]. The material acted like a shield," said Walter, leaving the delicate silk unharmed.

Synthetic nacre could be glued to a surface, or even painted on a wall, to make it flameproof. As if a cheap, strong, elastic and flameproof coating weren't enough, the new nacre also blocks oxygen, making it ideal for use in electronics.

"The area of applications for this materials is quite large," said Nicholas Kotov, a scientist from the University of Michigan who makes artificial nacre with the same base materials. Body armor for soldiers or police, fireproof coatings for buildings, casings for electronics and lightweight materials for more fuel efficient cars and aircraft are just a few of the research's potential applications.

Before synthetic nacre appears in consumer products a few kinks in the research need to be ironed out, said Kotov, including the appearance of some imperfections in the material. But the fact that the scientists can cheaply and easily produce synthetic nacre on this large of a scale is, according to Kotov, "quite amazing."