Researchers have created new plastic fibers that can detect and produce sound. When stretched, these strands could be used to make clothes that act as a microphone or generate electricity.

"You can actually hear them, these fibers," said Noémie Chocat, a graduate student in the materials science department at MIT and co-author of a paper describing the fibers.

"If you connected them to a power supply and applied a sinusoidal current" — an alternating current whose period is very regular — "then it would vibrate," Chocat said. "And if you make it vibrate at audible frequencies and put it close to your ear, you could actually hear different notes or sounds coming out of it."

Microphone check

The heart of the new acoustic fibers is a plastic commonly used in microphones. By playing with the amount of the element fluorine in the plastic, the researchers were able to ensure that the material's molecules remained "lopsided," with the fluorine atoms lining up on one side and hydrogen atoms on the other.

This asymmetry made the plastic "piezoelectric," meaning that it changes shape when an electric field is applied to it.

In a conventional piezoelectric microphone, this useful electric field is generated by metal electrodes. But in a fiber microphone, the drawing process — when the strand is pulled into being from a larger block of material — would cause metal electrodes to lose their shape.

So the researchers instead used a conducting plastic that contains graphite, the material found in pencil lead. When heated, the conducting plastic maintains a higher viscosity — meaning it yields a thicker fluid — than a metal would.

Not only did this prevent the mixing of materials that might wreck the fibers' properties, but, crucially, it also made for fibers with a regular thickness.

After the fiber was drawn, the researchers needed to align all the piezoelectric molecules in the same direction. That required the application of an electric field 20 times as powerful as the fields that cause lightning during a thunderstorm.

Sound results

In addition to wearable microphones, the fibers could be used as biological sensors for monitoring bodily functions. The tiny filaments could measure blood flow in capillaries or pressure in the brain, for example.

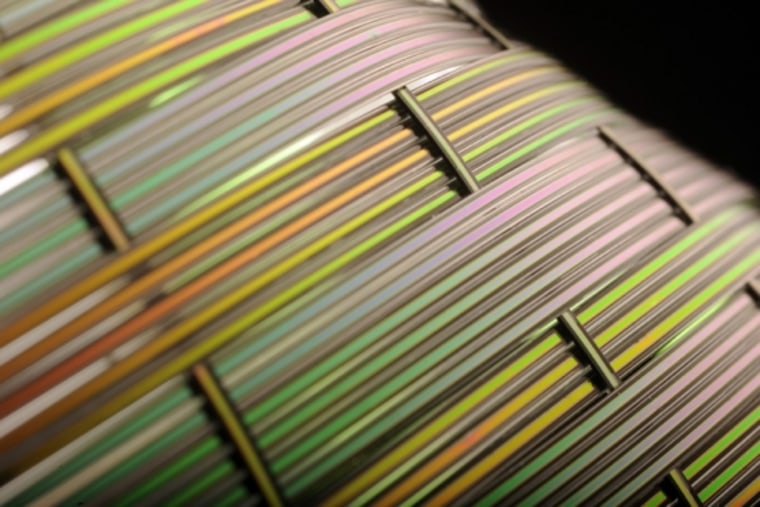

Other applications of the fibers include loose nets that monitor the flow of water in the ocean and large-area sonar imaging systems with much higher resolutions. A fabric woven from these acoustic fibers would provide the equivalent of millions of tiny acoustic sensors.

As it turns out, the same mechanism that allows piezoelectric devices to translate electricity into motion can work in reverse. "Imagine a thread that can generate electricity when stretched," said Zheng Wang, a research scientist at MIT and another co-author of the paper.

Ultimately, the team of researchers — led by Yoel Fink, an associate professor of materials science at MIT — hope to combine the properties of their experimental fibers into a single fiber. Strong vibrations, for instance, could vary the optical properties of a reflecting fiber, enabling fabrics to communicate optically.

Max Shtein, an assistant professor in the University of Michigan's materials science department, points out that other labs have built piezoelectric fibers by first drawing out a strand of a single material and then adding other materials to it, much the way manufacturers currently wrap insulating plastic around copper wire.

"(The MIT researchers have) the advantage of being able to extrude kilometers of this stuff at one shot," Shtein said. "It's a very scalable technique."

The paper describing the research appeared online July 11 and will be published in August in the journal Nature Materials.