Carbon nanotubes, the wunderkind molecules of the nanoworld, are finally showing strength in numbers. Researchers have now made large nanotube sheets that have many of the same star qualities as the prima donna-like single molecules, bringing the promises of nanotechnology a step closer to reality.

The flexible, transparent sheets can conduct electricity and emit light or heat when a voltage is applied, leading their creators to propose that our car windows and the canopies of military aircraft could contain nearly invisible antennae, electrical heaters for defrost, or informative optical displays.

These sheets, which are presently several meters long but could potentially be much larger, might also be useful in everything from flexible computer screens that could be rolled into a sack, to light bulb-like devices providing uniform lighting, to strong sails that could be propelled in space by sunlight.

“When you have a remarkable material, it’s easy to make advances in terms of applications,” said Ray Baughman of the University of Texas, Dallas, who led the research team that made the nanotube sheets. The scientists report their findings in the 19 August issue of the journal Science, published by AAAS, the nonprofit science society.

Growing a nanotube forest

Individual carbon nanotubes, long, cylindrical sheets of carbon atoms, are like minute bits of string, and researchers must assemble many trillions of these strings to make useful objects, including wide sheets and long yarns.

Until now, nanotube sheets have usually been made using versions of the ancient art of paper making, by filtering solutions of nanotubes and then peeling the nanotubes off the filter once they’re dry, which can take about a week. Baughman’s group has been working instead with nanotube “forests” that consist of nanotube bundles standing vertically.

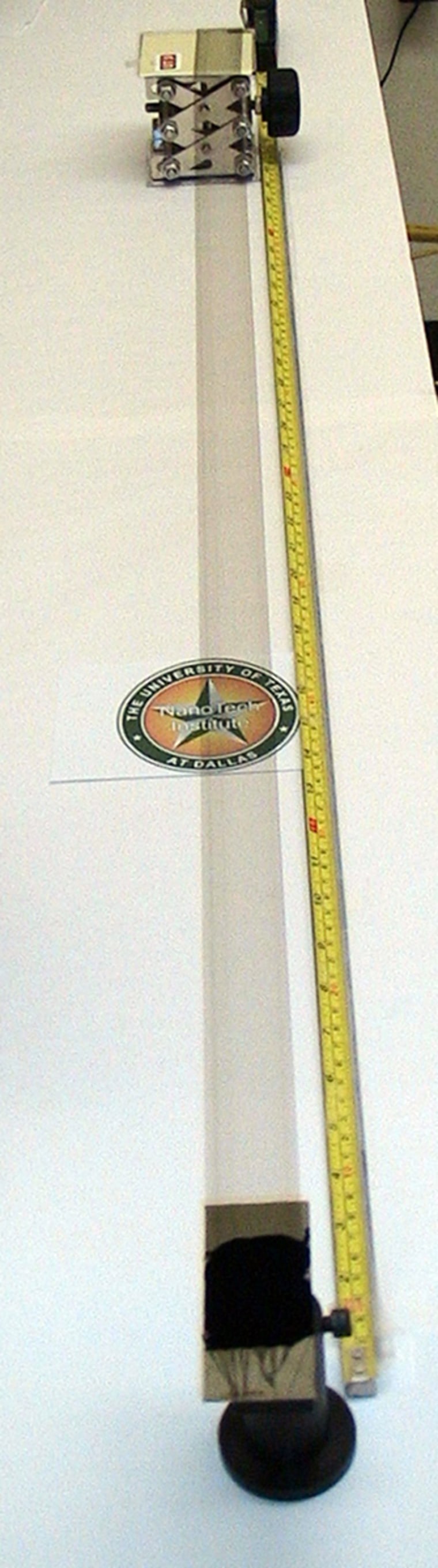

The researchers have now shown that by teasing nanotubes away from one side of a forest and attaching them to a strip of sticky tape they can draw the nanotubes into a continuous sheet. With this method they can produce nanotube sheets at up to seven meters per minute, which is fairly close to the rate of commercial wool spinning.

“It’s so surprising that this works,” Baughman said. “A trillion nanotubes must be automatically rotated by about 90 degrees and self-assembled in a parallel fashion for every meter-long, 7 centimeter-wide sheet that we make.”

Group dynamics in the nanoworld

Carbon nanotubes, which have high electrical conductivity, flexibility, and strength, are consummate individualists. When lumped together into a larger object, they often lose the remarkable properties that made them shine by themselves.

The new sheets have many of the same abilities as the single nanotubes, although their strength does decrease, becoming comparable to that of high-strength Mylar and Kapton, which are used for ultralight air vehicles. The nanotube sheets, however, can better tolerate extreme temperatures and exposure to sunlight and higher energy radiation in space.

As with individual nanotubes, when you pass an electrical current through a nanotube sheets, then things really get cooking. For example, if the nanotubes are electrically injected with electronic charge to slightly change their structure, this charge injection can make the sheets move, generating the force and stroke needed for an artificial muscle. Electrical current can also induce the sheets to emit heat at infrared wavelengths or higher-energy wavelengths of light.

Putting nanotube sheets to work

These tricks with nanotube sheets may help researchers make good on some of the promises that nanotechnology offers.

For example, Baughman and other researchers would dearly love to create artificial versions of the body’s muscle fibers, which can convert a chemical energy supply into mechanical work with even more efficiency than a car engine. Artificial muscles might be useful for prosthetic limbs, humanoid robots, and bird- or insect-like air vehicles that fly by flapping wings.

To get an artificial muscle material to move over large distances, researchers need a highly elastically electrode that will stay in contact with this artificial muscle during movement. To produce such a system, Baughman’s group attached a nanotube sheet onto a stretched piece of artificial muscle rubber. As the rubber was relaxed and then restretched, the nanotube sheet-electrode moved right along with it, without losing its electrical conductivity.

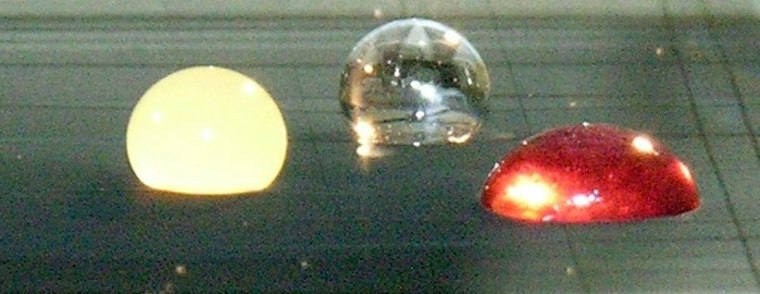

The researchers also used an electric current to make a nanotube sheet light up almost instantly, via incandescent heating (the same process that causes the filament in a light bulb to glow), offering possibilities for sensor light sources or headlights that don’t use filament-based light bulbs.

Using nanotubes, Baughman and his colleagues produced devices called “light emitting diodes” that manipulate the flow of electricity to generate light particles called photons. The beauty of these diodes is that they’re transparent, so if you stuck them on a window, for example, you’d have a light source that was nearly invisible until it was turned on.

Microwave radiation can be used to heat the nanotube sheets, so the researchers sealed a sheet between two plates of plexiglas with a few blasts from a kitchen microwave oven. This type of process could be used to make windows or transparent adhesive appliqués, say for heating car windows or perhaps the outer surfaces of airplanes, according to Baughman.

Other applications for these nanotube sheets may include solar cells, surfaces that store energy storage while offering structural support for electric vehicles, and electrodes for flexible electronic circuits. The authors also say that, with further tweaking, their nanotube sheets may be useful for building a space elevator tether. They’re planning to put the sheets to the test by entering the Spaceward Foundation’s Elevator:2010 contest.

Baughman noted that other research teams have also been able to make sheets and other types of objects with carbon nanotubes, but they aren’t transparent, strong, and highly conducting at the same time, like the ones he and his colleagues have made.

He also credits much earlier developments with paving the way to his research. The ancient Egyptians, for example, were early unknowing nanotech experts, using nanosized gold particles to make their beautiful glassware.