A geologist and an architect standing in a lab may sound like the start to a very nerdy joke, but a pair of these professionals have joined together to revolutionize the way scientists study structures, such as fossils, inside rocks.

Geologists use a variety of techniques to analyze fossils and other features trapped inside Earth's rocky layers. The most basic technique, dating back to the 19th century, involves slicing away layers of rock, taking pictures of each layer, and then recreating the full 3D shapes by connecting the dots between images. But this method is tedious and prone to human error.

"People have done this since Darwin," said Adam Maloof, a geoscientist at Princeton University who recently opened a rock imaging lab that brings this technique into the 21st century. "You can find very old articles from the 1870s where people sliced something five times, and then drew it, and put together a model of it."

Researchers have since devised more precise methods using electronic rock grinders and digital cameras, but, until now, the technique has not been automated.

Revolutionary redesign

Maloof has teamed up with architects at the Brooklyn-based Situ Studio to design a machine that automatically grinds layers as thin as 0.00025 centimeters — thinner than a human hair — and automatically takes high-resolution images along the way.

The grinding setup looks a bit like a mini car wash. On an automated steel shuttle, the rock first travels under misting nodules that clean away grime. Next, the rock passes back and forth under a 1-inch-thick (2.5 cm) diamond-studded grinding wheel, with a stream of water flowing to reduce dust. The sample then exits the grinder under a series of wiper blades and enters the limelight of an automated camera that snaps a shot from above. The shuttle then returns the rock to the start position, where the process repeats.

[ See photos of the lab and 3D rock models ]

Maloof wears mist-covered safety goggles as he describes the special features of the room: Double-width cinder blocks in the walls help reduce sound pollution outside, and a climate control system maintains a constant room temperature.

"The main source of error with a grinder like this is the expansion and contraction of the steel," Maloof said, with the machine humming loudly behind him, and all of lights shut off except a beam glowing from the camera area. "If you have temperature fluctuations at night, for example, the steel will change size and there will be an error."

Even the slightest shift can cause images to misalign and jeopardize the precision of the digital model.

The machine hums along day and night, and can grind through several inches of rock within 24 hours. A modern manual setup would take up to two weeks to cover the same area, and would not be as accurate.

Ancient life

Maloof's interest in high-precision grinding was sparked in 2009 when he and his graduate students discovered what they thought could be the earliest evidence of fossilized animal life. In a 640-million-year-old rock formation in South Australia, the team found large patches of small red flakes that varied in size and shape, and looked nothing like the surrounding rock. The group brought samples back to Princeton, where they spent two weeks manually grinding and imaging about half an inch (1.5 cm) of sample.

[ Photos: The World's Most Famous Rocks ]

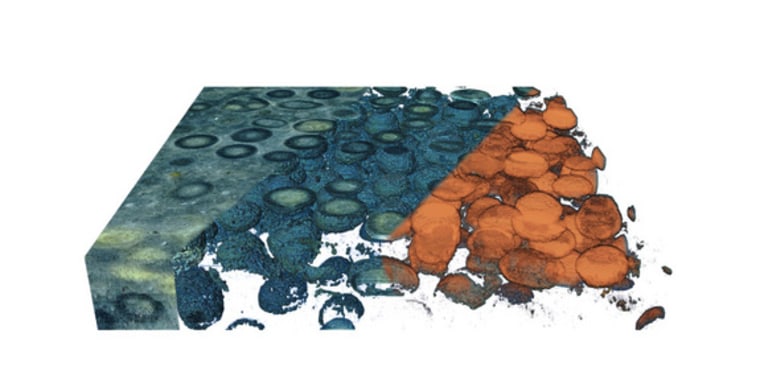

With the help of Situ Studio, the group created a 3-D model of their manual images and found what seemed to be remnants of ancient marine sponges. The team hopes to confirm this finding with their improved system.

"It definitely points to the potentials of interdisciplinary work," said Brad Samuels of Situ Studio, who helped Maloof choose the appropriate imaging and coding software, similar to what architects use to plan buildings. "The kinds of things that they needed in terms of tools and work flow are things that we have as a studio that we employ in designing spaces."

Oil drilling and meteorite dissection

A number of collaborators have already contacted Maloof about using the lab, including geologists in the oil industry wanting to analyze potential drilling rock, and geophysicists interested in dissecting meteorites.

"This is a very exciting instrument," said Roger Fu, a geophysics graduate student at MIT who will travel to the lab later this summer to study structures within meteorites that could help reveal information about how the solar system formed. "With the grinder, we should be able to get better 3-D maps of meteorites than ever before."

A downside of the grinder is that it ultimately destroys the sample, Fu said. Some researchers avoid this by using X-ray scanning technology to peer inside rocks, but X-rays blur with depth, and do not differentiate between different materials of the same density.

The beauty of rocks

For now, Maloof is working out the final kinks of the system using less valuable samples. The results, so far, have produced stunningly beautiful images of structures inside rocks.

"If you looked at these with an X-ray, you would see absolutely nothing," Maloof said, pointing to an image of sand grains coated in concentric layers of calcium carbonate.

The compiled images of this rock reveals the full spherical form of each sand grain for the first time since they fused together hundreds of millions of years ago.

Editor's Note: The author worked with Maloof's research group in 2010 and 2011 as a lab technician, and helped collect some of the fossil rocks from South Australia. She was not, however, involved in the analysis of the rock.

Follow Laura Poppick onTwitter. Follow LiveScience onTwitter,Facebook andGoogle+. Original article on LiveScience.