Tech analysts at IHS iSuppli have torn apart Motorola's latest phone, the Moto X, and found that it costs about as much to make as competing phones from Samsung and Apple — even factoring in the additional labor cost of assembling the Moto X inside the U.S. instead of Asia.

While the components, such as the display and processor, are still made at factories in Asia, the labor-intensive assembly of the Moto X is done here, as Motorola proudly announced prior to the phone's launch. Motorola was acquired in 2011 by Google for $12.5 billion; the Moto X is the first real collaboration between the two, and Google has been experimenting with building gadgets here.

But as it turns out, relocating that last step to the U.S. doesn't seem to affect the cost much. IHS iSuppli's teardown pegs the cost per unit at $225.65, all inclusive. Of that, the analysts estimate, only $12 comes from assembly costs — and doing that work in Asia would only have saved around $4.

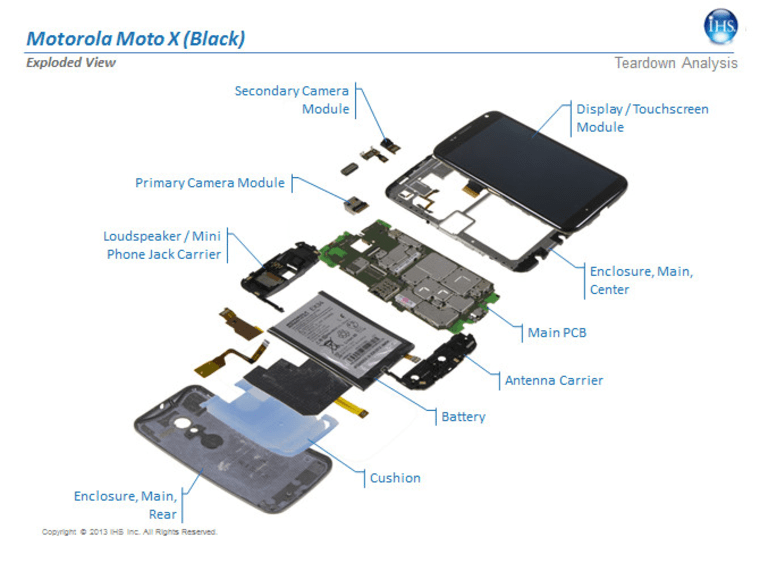

The most expensive component, as is usually the case, is the high-resolution touchscreen ($66), followed by the phone's processing chip ($30) and then its RAM and storage ($21).

A 16 GB iPhone 5 costs about $207 to produce, and sells for $649 unlocked. The Galaxy S4 (also 16 GB) costs about $237 to make, also selling at the same price point, between $620-$650. Meanwhile, the Moto X undercuts them both at $579 without a contract. With a two-year contract, it's $199.

The Moto X is available on AT&T now (you can design your own), and will arrive at Verizon Thursday. Other carriers are expected to support and carry the phone over the next few months.

Devin Coldewey is a contributing writer for NBC News Digital. His personal website is coldewey.cc.