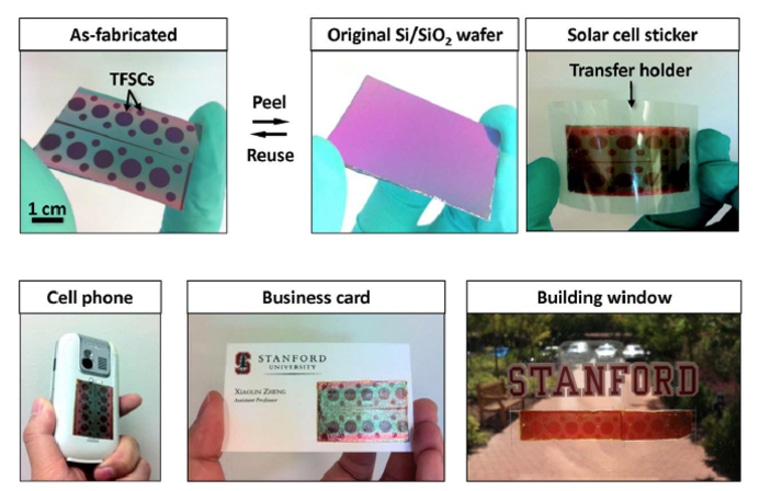

Business cards, cellphones and windows could all get a little boost from a sticky new invention. Researchers have created thin, flexible solar cells that can stick to paper, plastic, glass and many other materials, just by using double-sided tape.

"Now you can put them on helmets, cellphones, convex windows, portable electronic devices, curved roofs, clothing — virtually anything," Xiaolin Zheng, a mechanical engineer at Stanford University who led the development of the new solar cells, said in a statement.

The cells are a step toward turning more and more everyday items into either electronics or solar power-harvesting surfaces. Solar cells placed on windows could help a building absorb more solar power than roof installations alone, for example. And a combination of flexible solar panels and electronics could lead to products such as electrified "smart" clothes that control a connected smartphone.

Zheng and her team's creation may help smart clothes come a little sooner, too. The techniques they used could help engineers make flexible circuits, transistors, liquid crystal displays and other electronics, the researchers say.

Solar panels currently in use must have a glass or silicon backing, so they're necessarily rigid. But researchers in several labs are trying to change that. Other efforts TechNewsDaily has covered include solar cells printed on paper and a kind of solar power glitter.

Zheng and her team's invention, which they've called the peel-and-stick process, gets around one major difficulty in making flexible solar cells: manufacturing the solar cells onto a non-rigid surface. In the peel-and-stick process, thin-film solar cells are still manufactured on a stiff, silicon wafer. But, in a major difference, the wafer is covered in nickel, which makes Zhang's process possible.

Once the thin-film solar cell is ready, researchers soak it in room-temperature water. The water molecules get between the nickel and the silicon, so that, eventually, researchers can peel the solar cell away from the rigid wafer. Then it's just a matter of adding some double-sided tape or another adhesive to stick the thin-film solar cell anywhere users want.

The solar cells don't lose any of their 7.5-percent efficiency after being peeled from their silicon backing and stuck somewhere else, Zheng said. The silicon backing often may be reused to make more solar cells.

Zheng and her colleagues published a paper about their work Dec. 20 in the journal Scientific Reports.

Follow TechNewsDaily on Twitter @TechNewsDaily, or on Facebook.

- 5 Easy Ways to Go Green — and Save Money

- Wearable Electronics Pave Way for Smart Surgeon Gloves

- 8 Tips to Protect Your Home During the Holidays

Copyright 2012 TechNewsDaily, a TechMediaNetwork company. All rights reserved. This material may not be published, broadcast, rewritten or redistributed.