Athletes aren’t the only ones competing head to head during the Winter Olympics: There are technological duels as well, powered by years of design work and wind tunnel tests. Designers and engineers have been laboring to shave thousandths of a second off the times of speed skaters, ski racers and bobsledders — and in Salt Lake City they’re finally going for the gold.

EVEN THE MOST gung-ho geek would admit that technology alone can’t turn an also-ran into a medal-winner. But at the elite athletic level, in sports that depend on going as fast as you can, drag and friction could make the difference between bronze and gold.

At the 1998 Winter Olympics, the star of the high-tech sweepstakes was the clap skate, a boot with a hinged blade that helped skaters break records galore. In 2000, it was the “sharkskin” full-body racing suit, designed to reduce water drag for record-setting swimmers.

Well-suited rivals

This year, two companies are rolling out high-tech suits that they hope will do for speed skating what sharkskin did for swimming.

After years of secrecy, Nike unveiled Swift Skin — which uses six fabrics designed to address specific aerodynamic properties of different body parts. Swift Skin will be worn by speed skaters from the U.S., Dutch and Australian teams.

Descente, meanwhile, is equipping athletes from Canada, Spain and Switzerland with three versions of its Vortex suits, tailored for speed skaters, Alpine skiers and ski jumpers. The Canadian speed-skating suits have already created a fashion stir because of their bold “visible muscle” design — and because they’re so sheer and skin-tight that Olympic sprint skater Krissy Myers’ happy-face underwear could be seen through the suit during last month’s world sprint championships.

But when it comes to the high-tech innovations woven into both the Swift Skin and the Vortex suits, there’s more than meets the eye.

“If you ran your hand over the garment, you could feel a difference, but just by looking at it I don’t think you would notice anything different,” said Descente spokeswoman Stacy Tomasic.

The Vortex suit has raised rubber ridges that channel the airflow to reduce drag, while Swift Skin uses strategically placed panels of textured fabric for the same purpose. Both companies compare the effect to the dimples that break up turbulence as air flows around a golf ball.

Both companies also were careful about releasing too much too soon about their technology. Nike, for example, rented the Utah Olympic Oval for testing sessions that were closed to outsiders.

“Any time any company is introducing new technology, certainly around a particular event, security is going to be very high, because ideas are our stock and trade,” said Rick MacDonald, Nike’s innovation director.

Testing the wind

Wind-tunnel testing has played an essential role for Nike’s Project Swift as well as most other preparations for Olympic speed sports. “Air resistance can be a negative factor in any sport where someone has to move themselves,” MacDonald said, “and the wind tunnel is the most accurate way to measure wind resistance on an object.”

MacDonald recalled that researchers began by studying aerodynamic drag on fabric-covered cylinders in a Seattle wind tunnel, then moved up to mannequins and plastic body parts. Finally, tests were conducted with Olympic speed skater Jason Headstrand standing in the wind tunnel.

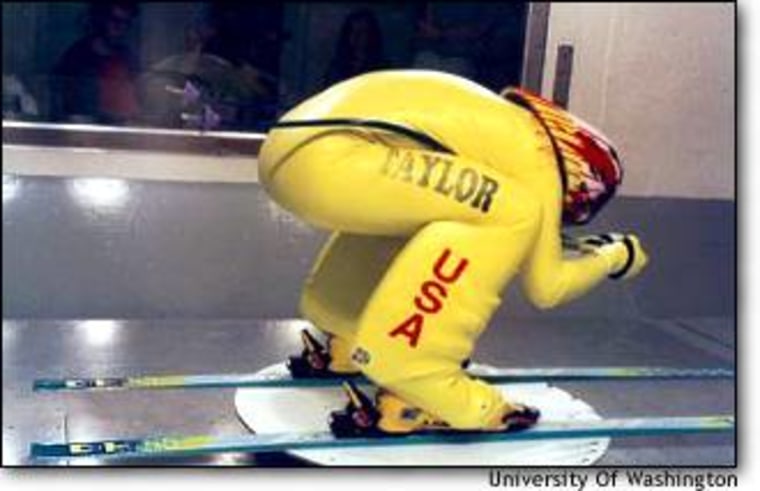

Downhill skiers also use wind tunnels extensively, not only to test clothing and equipment, but also to refine their moves so they minimize atmospheric drag on the slopes.

“The main focus ... is really doing a matching between skiing and aerodynamics, a choreography between the two,” said Michael Holden of the Calspan-UB Research Center in Buffalo, N.Y., who has worked with the U.S. and Canadian Olympic ski teams.

Holden conducts tests in wind tunnels as well as on the slopes, using special force-measuring devices inserted between the skis and boots. The data show exactly how the skiers are putting pressure on the ski edges as they turn. “Sometimes video doesn’t always tell the truth,” Holden said.

But maximizing a skier’s performance is an art as well as a science, he cautioned.

“You can be totally misled,” he said. “You ski basically with your chest open, whereas when you get in a wind tunnel it feels best when you have your back flat, and that’s not what happens when you’re in a real race.”

Holden said the data analysis helps most in seeing how skiers make their transitions along the course, so they can make adjustments that cut down on drag without cramping their style.

“How quickly you move on the ski, how you put the weight on the skis, and where the pressure point is — you can really see the anatomy of a ski turn,” he said. “That’s really big time, and we haven’t exploited that a lot yet.”

Sled studies

Wind tunnel tests also point up aerodynamic adjustments that athletes can make in the Olympic sled sports. Holden, who works with the luge and the skeleton, said riders should actually blend in with the equipment they ride.

“If you were to have a person lying in a luge position on a 2-by-4, the drag actually drops when they sit on a luge,” he said.

The aerodynamics of the suits and helmets are “hugely important,” he said.

“It really helps to have a suit that doesn’t flap around, that doesn’t microvibrate,” Holden said. “That means you’d better be wearing a brand-new suit.”

Sometimes the technological competition can go too far: For example, in the mid-1990s, the sports outfitter Spyder came out with a competition ski suit dubbed Speedwyre, which incorporated strategically placed seams and cords to cut down on drag.

“We had so many wins with racers wearing that suit that a team that came in at third place decided to complain,” said Laura Orlowski, Spyder’s promotions and media manager. The International Ski Federation banned the fabric from use in 1997, and this year Spyder is providing the U.S. downhill team with suits that are maximized for aerodynamics without running afoul of the Speedwyre ban.

“We could make a much faster fabric,” said Andy Templin, Spyder’s corporate sales manager, “but with the 30-milliliter standard, there’s not a whole lot we could do.”

Nike’s MacDonald said he’s confident the Swift Skin technology is consistent with the Olympic speed skating rules, and he’s looking forward to seeing how the competition unfolds — technologically as well as athletically.

“It would be fair to say that we’ll be paying attention to how the different skaters from the different countries do compared with how they did before,” he said.

But in the end, MacDonald knows that no medals are going to be handed out for the suit that makes the biggest reduction in aerodynamic drag.

“Ultimately, we’re sports fans, and we just want skaters to go fast,” he said. “It’s not so much about competing with another company. Helping the athletes is the bottom line.”