Did you hear the one about the microbes that send out electricity through their hair? Or the one about the germs that actually clean up toxic algae-ridden water? How about the bacteria that build up artificial bones or manufacture medicine?

They may sound as outlandish as the stupid pet tricks you see on late-night talk shows, but the tricks that microbes do could end up improving lives and saving energy.

Researchers from around the world swapped their tales of not-so-stupid microbe tricks over the weekend at the Society for General Microbiology's meeting at Herot-Watt University in Edinburgh, Scotland. Here's a sampling of the stories:

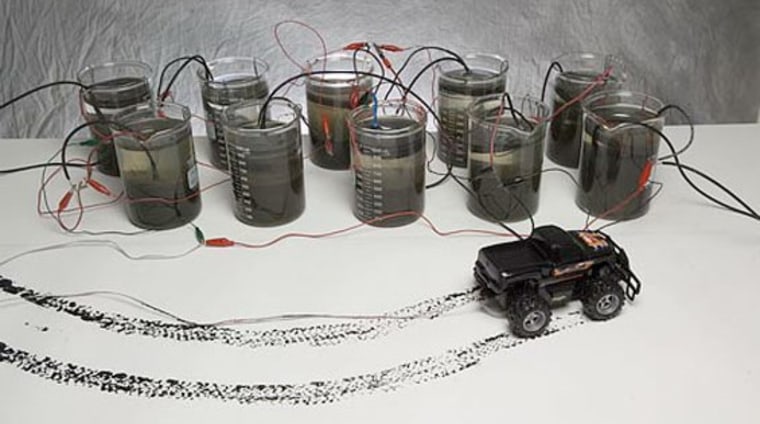

Hairy bacteria for fuel cells

Tiny filaments appear to enhance the flow of electricity generated by a strain of sulfur-eating bacteria known as Geobacter sulfurreducens KN400, according to Derek Lovley, a professor at the University of Massachusetts at Amherst.

"The filaments form microscopic projections called pili that act as microbial nanowires," Lovley said in a news release. "Using this bacterial strain in a fuel cell to generate electricity would greatly increase the cell's power output."

Geobacter, which can convert marine waste products into electricity, has long been considered a potential source of power for fuel cells. Lovley and his colleagues are developing such fuel cells to power monitoring devices in environments where it's difficult to replace batteries. KN400, for example, could provide the energy for deep-sea sensors that monitor turtle migration, Lovley said.

Mini-factories for medicine

Canadian researchers have turned a harmless strain of bacteria into a protein production factory by adapting a single protein on its surface. Such "factories" could eventually produce vaccines, anti-infection agents and anti-diarrhea drugs, said John Smit of the University of British Columbia.

The microbe, Caulobacter crescentus, secretes a protein that assembles itself into a surface structure Smit calls the "S-layer." Researchers found that the bacteria's self-assembly system could be modified to bring therapeutic proteins up to the surface, making it easier to purify bioengineered medicines.

"We can make the bacterium into a protein pump, secreting over half of all the protein it makes as engineered S-layer protein," Smit said in a news release. "Applications of S-layer display that we are currently developing include anti-cancer vaccines, an HIV infection blocker and agents to treat Crohn's [disease] and colitis, and diarrhea in malnourished populations."

Bacteria vs. toxic algae

Blue-green algae are becoming a scourge in areas of the globe's oceans as well as inland bodies of water. Algal blooms can produce toxins called microcystins that can be ingested by animals and humans when they drink, swim or bathe in contaminated water.

Researchers at Robert Gordon University in Scotland have identified more than 10 strains of bacteria that can break microcystins down into harmless byproducts. Six of the strains were tested with contaminated river water under conditions that simulated real-world conditions, and all six were able to break down the toxins, the researchers reported.

"The costs of advanced water purification strategies are beyond most of the world's population," microbiologist Aakash Welgama said in a news release. "Using bacteria to remove microcystines from water provides a reliable, cost-effective purification system, which does not involve any use of harmful chemicals."

Bone-building bacteria

A strain of bacteria known as Serratia can be enlisted to manufacture the "glue" for stronger, more durable bone implants, researchers from the University of Birmingham in England reported.

The research team found that the bacteria can stick tightly to surfaces such as titanium alloy, polypropylene plastic, porous glass and polyurethane foam by forming a biofilm layer that contains a polymer known as hydroxyapatite, or HA. After a thick coating of HA builds up on the surface, the material is dried and heated.

"The bacteria are destroyed by heating, leaving just the HA stuck to the surface with their own glue — rather akin to a burnt-milk saucepan," the University of Birmingham's Lynne Macaskie said in a news release.

Most artificial bones today are made from materials that are coated with a spray-on layer of HA polymer, but the artificially coated material isn't as strong as the biofilm-based material. Moreover, the spray-on material doesn't cover the nooks and crannies of bone material as well as the bacteria do, the researchers said.

The bone-building bacteria aren't quite ready for prime time, Macaskie cautioned. "We need to do more work actually to turn the materials into materials we can use in biomedicine and the environment," she said. "Then they need to be tested in real-life situations with clinical and environmental trials."

More on |

This report also appears as a .