A cotton shirt that could warn its wearer of allergens or instantly tell where a soldier is bleeding is being developed by scientists at the University of Michigan.

The scientists created the electrically conductive cloth by dipping cotton fibers into a vat filled with water, a conductive polymer, and carbon nanotubes. The tubes soaked into the cotton fibers and remained after the cloth was dried.

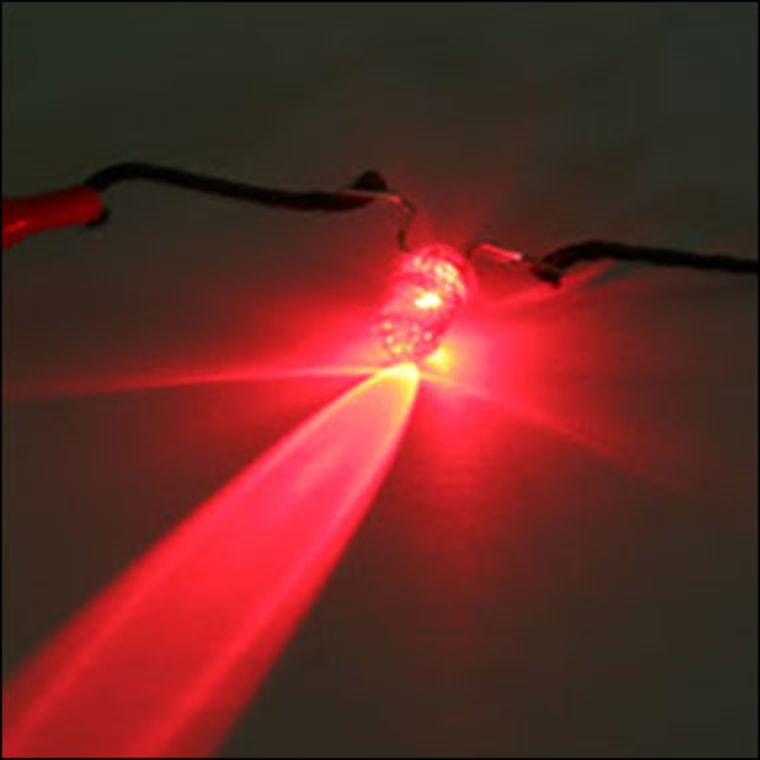

"The process is quite elementary," said Nicholas Kotov of the University of Michigan, the lead scientist on the project. "But [the thread] is able to conduct electricity almost like metallic wires, so we were able to power a light emitting diode."

Carbon nanotubes are tiny, hollow cylinders made of pure carbon atoms and arranged in a flat, repeating hexagonal pattern. Diamonds, also composed of pure carbon, are, for comparison, arranged in a three-dimensional diamond shape.

Carbon nanotubes are lightweight and strong, conduct electricity, and have various optical properties that make them interesting to scientists. The current research was published in the online journal Nano Letters.

The number of nanotubes in the material varies depending on the number in the vat or the number of times the fabric is treated. The more nanotubes in the cloth, the more electrically conductive the cloth is.

To prove that the cloth will hold a charge, the scientists attached a thread to a light-emitting diode and watched as it shined.

While stringing a shirt with tiny lights is one potential use for the thread, a more likely use is for clothes that detect airborne allergens or human blood, or for gloves that can manipulate touch screens.

An entire shirt doesn't have to be dipped in carbon nanotubes; just a few threads need be woven in. This efficiency, along with increasingly cheap ways to produce carbon nanotubes, should help keep the cost down.

"If you want to make a whole shirt from that type of cotton, it may be expensive," said Kotov. "But then again, some cotton shirts cost a substantial amount, so I don't believe it will be cost prohibitive."

The cloth, of which there is now roughly one square foot, still looks and feels like cotton, said Kotov. "What we have right now is very much like the fabric you find on jeans."

The ease and sophistication of the technique is what appeals most to Juan Hinestroza, an assistant professor in the Fiber Science and Apparel Design Department at Cornell University.

"It's a combination of a natural material and a synthetic material that is very simple but also quite functional," said Hinestroza. "I think the implications of smart and interactive clothing are huge."

Hinestroza expects that electrically conductive, nanotube-based clothing could be found on store shelves within a few years. That should be plenty of time to answer questions about the safety of carbon nanotubes in such close and prolonged contact with human skin.

"All this is conditioned on the fact that carbon nanotubes are benign and biocompatable," said Kotov. "The question is still not completely resolved, but lots of published research says that as a solid material, carbon nanotubes are very benign."