If you want to build a molecular-scale computer chip, or a minuscule sensor that detects the slightest whiff of an airborne toxin, you’re going to need some tiny builders to help put these gadgets together. In Friday’s issue of the journal Science, published by the American Association for the Advancement of Science, researchers in Texas show how they hired a virus as their nano-construction worker.

Genetically engineered to grab up dots of zinc sulfide, these “viral semiconductors” arrange themselves into highly ordered structures that may serve as the raw material for future nanoscale devices.

“We want to build things that are as small as the length across a strand of DNA. When you’re building things as small as a virus, it makes sense to try to use the biology that already works at this size,” explains Angela M. Belcher of the University of Texas.

The building blocks of nanotechnology are materials with orderly, often repeating patterns on the scale of a billionth of a meter. It’s nearly impossible for researchers to directly create large arrays of these materials with such stunning precision, so scientists seek out systems that can spontaneously arrange themselves. Many biological materials, including viruses in solution, have this promising “self-assembly” quality.

Millions of viruses in solution can line up and stack themselves into layers, creating a material that flows like a liquid but maintains an internal pattern. By changing the solution’s concentration or applying a magnetic field, scientists can force new patterns and create different liquid crystal structures.

Designer Viruses

If tiny semiconductor particles could be attached to these orderly viruses, the viruses could do all the tedious and fine work of creating a highly organized nanomaterial, Belcher and her colleagues reasoned. So they set out to design a virus that would recognize and attach itself to zinc sulfide nanocrystals.

The researchers began by genetically engineering their chosen nontoxic virus to carry random bits of protein in its outer coat, and comparing each altered virus’ ability to latch onto zinc sulfide particles. Belcher and the others aren’t exactly sure how the different protein motifs bind to the crystals, but they suspect that the two hook up much like an antibody and antigen.

“We think it might work like a lock and key, with the two surfaces complementing each other,” says Belcher.

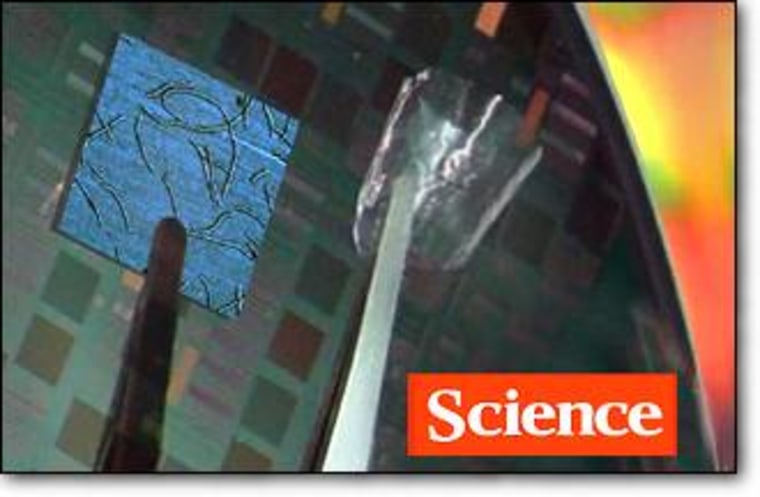

After extensive screening, the scientists chose the “best binding” virus and allowed it to infect bacteria where it could make millions of copies of itself. Added to a zinc sulfide solution, the viruses attached themselves to the semiconductor material, grew zinc sulfide nanocrystals at their ends, and assembled themselves into a highly ordered hybrid film with the piggybacked particles. By tinkering with different solution concentrations and applied magnetic fields, Belcher and colleagues were able to alter the stacking direction of the film’s layers.

Designer devices

Although the zinc sulfide hybrid is their first complete liquid crystal system, the research team has already identified other engineered viruses that can bind to other semiconductor crystals, such as cadmium sulfide, and magnetic materials.

The viral films can be stored at room temperature for at least seven months without diluting their concentration or affecting the ability of viruses to infect bacteria.

“We’ve found that this is a reversible process, that you can completely disassemble and reassemble these films, which is interesting from a biotechnology aspect,” says Belcher. The researchers are pursuing the intriguing possibility that these films might be a new way to store high-density DNA without freezing.

At this point, the technique is “pretty basic, a way of arranging electronic materials where you want them to be,” says Belcher. Her team will be spending the next year trying to make simple devices out of this material, with the hope that these materials can be used in self-assembling computer chips, optical devices and sensors that detect biowarfare agents or chemicals.